Rapid Prototyping & Casting

Fast-Track Production

with 3D Printing

IPC Foundry Group offers high-precision 3D printing services to streamline prototyping and kick-start your casting projects. From concept to cast, get to market quicker than ever with IPC.

Get it Right + Save Time & Money

Why Use 3D Printing?

Whether you're looking to test designs quickly, reduce unnecessary costs, or shorten your production timeline, 3D printing with IPC helps you move production forward faster, smarter, and more efficiently than ever before.

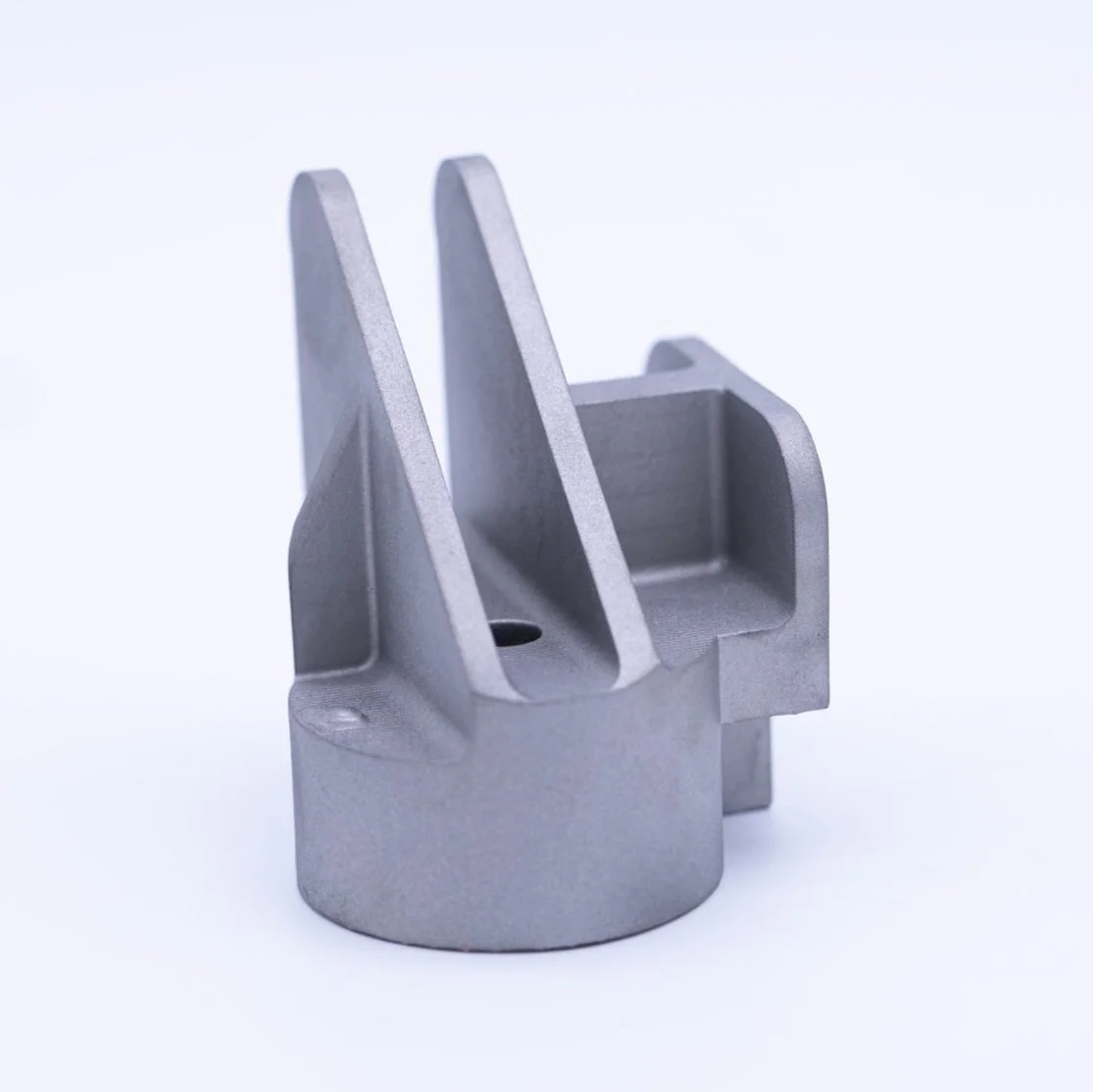

01 Prototyping

Make internal decisions on design, fit, and function with 1:1 models.

-

Functional Feeback

Quick small batch runs to prove/test designs before moving into time and cost sensitive tooling.Iterate Fast

Designs can be printed, tested, and revised in a matter of hours or days—not weeks.Get Creative

Explore multiple materials, surface finishes, colors, etc.Production Ready

Seamlessly transition into casting following prototyping and development.

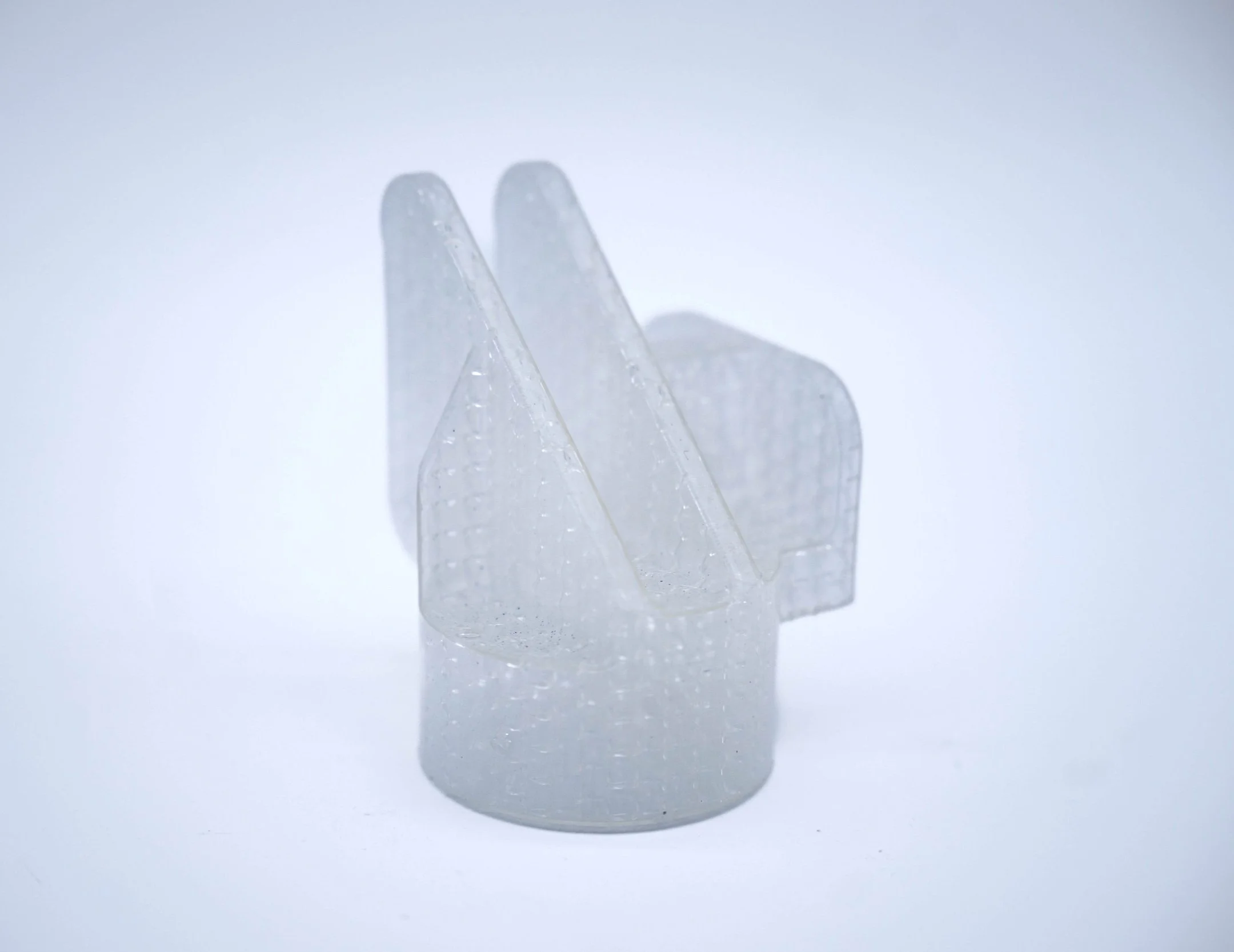

02 Streamline the Casting Process

Have finished castings in hand, before traditional tooling would be completed. Get 1st articles in days, not weeks.

-

Bypass Tooling

Full production ready patterns if quantities don’t justify tooling costs. Perfect for small batches or one off parts.Legacy Parts

Excellent for legacy part reproduction. Create parts when you need them. (automotive, food processing, agriculture, mining, and more)Urgent Projects

Full production ready patterns for urgent projects or if tooling lead times are too long to wait.Significantly Reduce Time to Market - Have finished products in hand before traditional tooling is completed.

Cut time, Not Corners

Highly precise, complex designs can be printed in just a few hours.Optimize Traditional Casting

Utilize 3D printing to optimize a full-scale production run (with tooling). Create and test gating, make fixtures, grippers, and other production items to help with the manufacturing process.

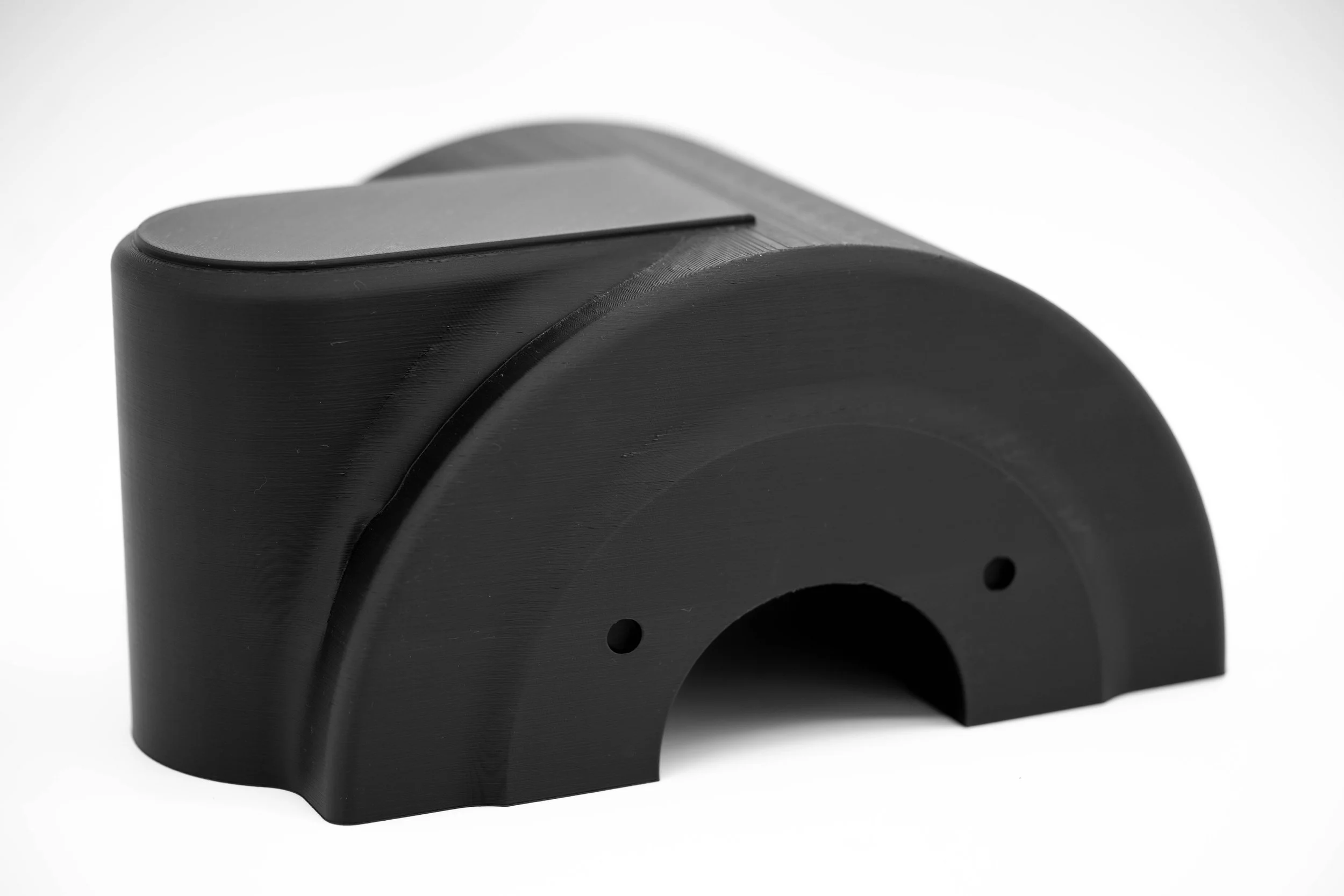

03 Cost Savings

Bypass expensive tooling, cut labor costs, and save big on your investment casting project.

-

Bypass Tooling

Traditional Tooling is time and cost intensive. 3D printing sidesteps the need for tooling. Perfect for small batch, one offs, or legacy parts.Cut Labor Costs

3D printing streamlines the casting process and reduces manual processes, saving you time and money.Automated Printing

Parts print automatically around the clock. Production never stops.Convenient Casting

Save patterns digitally for future production runs - no bulky physical patterns required.

Get to Market Fast

Sidestep Tooling with

3D Printing

Traditional investment casting utilizes tooling to create wax patterns for casting; this can be time-consuming and prohibitively expensive for some projects.

For small-batch, rush projects, large-format parts, and legacy part reproductions, 3D printing can be a game-changer in both turnaround times and cost savings. Interested? Contact our team today and learn how IPC can help your business.

Your Production Partner

Why Use IPC?

Experience

45+ Years of Casting Experience

IPC pours millions of pounds of metal components each year for customers in over 130 unique industries.

Dedicated Engineering Team with CAD/3D modeling expertise

Scalable Casting Solutions

At IPC Foundry Group, we invest alongside our clients to provide a partner and service you can count on for years to come.Satisfaction guaranteed

in every metal partUS-Based Manufacturing

in Texas and UtahOffshoring Made Easy

Move production overseas without headaches or off-hour meetings with our international partners.

Capabilities

A One Stop Shop

All of your metalworking needs in one place, from prototyping and production to machining, testing, certification, and shipping.

In House 3D printing

Iterate quickly. Get same-day updates to prototypes and production patternsComprehensive casting solutions:

Product development, prototyping, casting, machining, finishing work all done in our Texas and Utah foundries.24/7 Production Cycles

Cutting edge automation in each of our facilities means that your parts are produced around the clock.

Materials

Alloys for Any Application

Hundreds of alloys available to serve customers in any industry.

Ferrous

Stainless (300 and 400 series, PH, duplex, heat resistant) Steel (carbon/low-alloy, tool) Cast Iron , Aluminum, Titanium, and more.Non-Ferrous

Nickel-base, Cobalt-base, Brass, Copper, and moreCompliance:

Heat Treating, 3rd Party NDT X-Ray, PT,VT, MT), Plating, Solidification Modeling, Tooling Repair & Storage,

From CAD to Casting

See Us In Action

At IPC, our expert team and modern foundries are built to move at the speed of your business. Want to see us in action? Click the link below to see how we helped one customer bring a large-format casting to life in just 8 weeks, thanks to 3D printing and our streamlined production.

Get Started

Get a 3D Printing Quote Fast

01

Prepare and Send a 3D Model

Have a 3D model in mind? Sent it to our team! We’ll review the file and be in touch in as little as 24 hours.

No File? No worries! Our engineering team can help you prepare one from an existing part or from scratch!

02

Collaborate with Our Team

After we review your project, chat with our team to talk about production options, timeline, secondary operations, pricing, and anything else to get you the best quote possible.

03

Get Prototyping or Start Production

Let us get to work! We’ll print prototypes to help you settle on form and function

Then, when you’re ready, kickstart a full production run of precision castings.