Made in Utah

Utah’s Own Investment Casting Foundry

Just off of the I-15 in the shadow of the Wasatch Mountains is the home of the IPC Foundry Group’s Utah facility. For over 40 years, we’ve called Lindon, Utah home. Across our four-decade history, we’ve served dozens of industries throughout Utah, Colorado, Nevada, California, Washington, the Intermountain West, and Canada.

We’ve dedicated ourselves to creating and staffing a state-of-the-art foundry so you can take the stress and guesswork out of manufacturing. With our 24/7 production cycle, precision-focused automation, and dedicated team members that keep you appraised every step of the way, IPC is the perfect partner for your casting needs.

Trusted for Over 40 Years

Casting Millions of Parts for Dozens of Industries

IPC brings extensive expertise to the table, having accumulated years of experience in producing tool steels and casting components for a diverse range of industries (rail/light rail, consumer products, solar, food processing, medical, oil & gas to name a few).

From agriculture to outer space, our castings have nearly limitless applications and potential. Check out a few of the industries we’ve served by clicking the link below.

Why Choose the IPC Foundry Group?

IPC Utah utilizes its unique capabilities and skilled team members in tandem with our entire network of foundries, machining, and finishing partners. This allows us to scale to your needs, even if that means investing in new equipment or facilities to get your product to market. Whatever the need, IPC strives to be a partner you can count on time and time again.

01 Industry Leading Automation

From optimizations in onboarding to cutting-edge robotics that deliver blistering fast turnaround times, IPC has introduced automation to every step of the production process. This means shorter lead times and a hassle-free production process for you!

02 Modular Manufacturing

We realize that one-size-fits-all doesn’t always work when it comes to your business. Whatever your project demands, IPC is committed to utilizing our team and network of metalworking partners to make it happen. Sometimes this even means making an investment in new equipment to help you meet your production goals.

03 Your Onshoring Partner

IPC focuses on creating long-term manufacturing relationships. We navigate the complexities of onshoring, providing not just casting solutions and UL-certified metalwork but strategic partnerships that contribute to the success of our clients as they bring their production back to the United States.

A Brief History of

the IPC Foundry Group - Utah

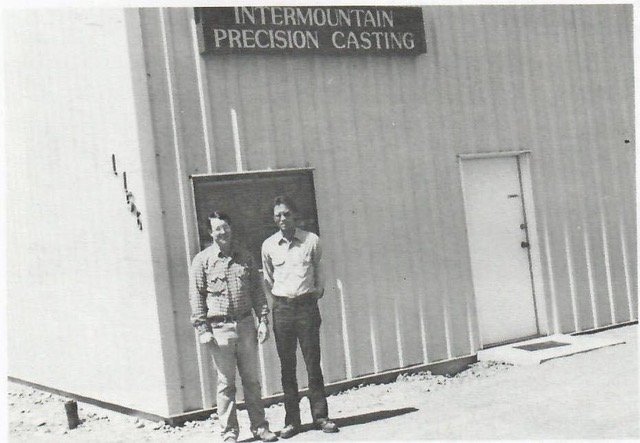

Intermountain Precision Casting

Intermountain Precision Casting began business in 1980. After growing up in the investment casting industry in California, Larry Veenker brought his knowledge of the lost wax process to Brigham Young University, where he taught for several years. Over time, Larry began preparations for starting an investment casting foundry in Utah. His first step was calling upon the organizational and management skills of John Williams to help run the company. Soon after, they opened their doors in Lindon, just 30 minutes from Salt Lake City, and began serving numerous businesses throughout the state. Over time, the company grew and expanded its footprint into dozens of industries throughout the US and Canada.

Modernization

For years, we built a bedrock and reputation of treating customers right and focusing on unique nuances and details of every project. However, the demands of the industry necessitated that we adapt in order to survive.

2007 marked a turning point for us; a customer we had been serving for over 25 years left for a different foundry because we did not have the capacity to match their growth. It became clear that without modernizing our equipment, we could not keep up with the demands of the future.

We hit the ground running, adding new robotics, bringing in more staff, using state-of-the-art software, and expanding our foundry in 2015. These changes have allowed unprecedented growth and an even higher standard of excellence for our castings. Today, our Lindon foundry's production capacity is 15 times greater than five years ago.

The IPC Foundry Group

As our growth trajectory continued, we forged partnerships with numerous machining, prototyping, 3D printing, finishing, and other metalworking facilities. In 2022, we marked a significant milestone by acquiring Highland Lakes Casting, now seamlessly integrated into the IPC Foundry Group as our Texas facility. Through substantial investments totaling millions of dollars, we've modernized production throughout our facilities, created numerous additional jobs, and expanded our reach across a multitude of industries.

To underscore the breadth of our enhanced network of investment casting and metalworking services, we proudly unveiled a unified identity in late 2023—the IPC Foundry Group.

With substantial investment, IPC is poised to not only uphold its 40+ year legacy of producing quality castings but also embrace new opportunities and challenges in an ever-evolving industrial landscape. We look forward to serving you even better as the IPC Foundry Group!

How it Works

IPC Foundry Group FAQs

Which of Your Foundries Will I Work With?

While our operations span multiple locations, we function seamlessly as a unified entity. Throughout the onboarding process, we collaborate closely with you to guarantee a smooth production cycle. Leveraging our team of experts both domestically and internationally, we are dedicated to assisting you in achieving each of your project's goals.

How will I be Appraised on my Project?

For each project, we assign a dedicated sales + technical support representative. They will keep you appraised throughout the production cycle and always be available to answer any questions that you may have.

Can You Meet My Production Needs?

When asked this question, our default answer is yes! We continually invest in our facilities to meet the ever-changing demands of the metalworking industry. Contact us today and one of our team members will help tackle the unique challenges of your project.

US-Based Manufacturing

Our Commitment to Onshoring

Regardless of your project’s scale, IPC is committed to providing a seamless transition to stateside manufacturing. With a history of serving both midsized and large corporations, IPC is primed to help you on your path to UL certification and is eager to be a strategic partner contributing to your product's success.