Stay in the know

Join Our Mailing List

Stay up to date with IPC, the foundry that constantly invests in your success. Subscribe for monthly updates on our recent facility upgrades, new capabilities, upcoming events & tradeshows, certifications, and all things investment casting.

News

Our Team

Introducing Mike Snow

IPC Utah’s New GM

We’re thrilled to announce that Mike Snow will be joining the IPC team as the new General Manager of our Utah facility. Learn more about Mike and hear from Blake Williams, President of IPC Foundry Group, in this article.

Read More >

A Case Study

How IPC Global Sourcing Delivers

A customer’s frustrations with sourcing their parts overseas led to a success story with our new service, IPC Global Sourcing. Learn all about this service through the lens of an IPC customer!

Facility Upgrades

Everything is Bigger at IPC Texas!

2025 brought a number of massive updates to IPC’s Texas facility. Read all about our 8x increase in capacity and how our engineering team tackled the upgrades for $2M less than quoted by an external firm.

Facility Upgrades

How IPC Increased Capacity by 33%

IPC Foundry Group is reactive to the needs of our customers. Operating at near capacity prompted us to upgrade our dipping room, creating improved yields, faster delivery, and increased production capacity.

Certifications

IPC Foundry Group is JCP Certified!

As of July 2025, IPC Foundry Group is JCP Certified under DD2345 and approved to receive unclassified DoD technical data. Learn more about our certification and how IPC supports U.S. Defense OEMs with investment castings.

3D Printing

Delivered in 8 Weeks: How IPC Tackled a Rush Project with 3D Printing

Discover how IPC met an aggressive deadline by combining teamwork, on-the-fly problem solving, and innovative 3D printing - turning a complex casting project into a repeatable success story for future customers.

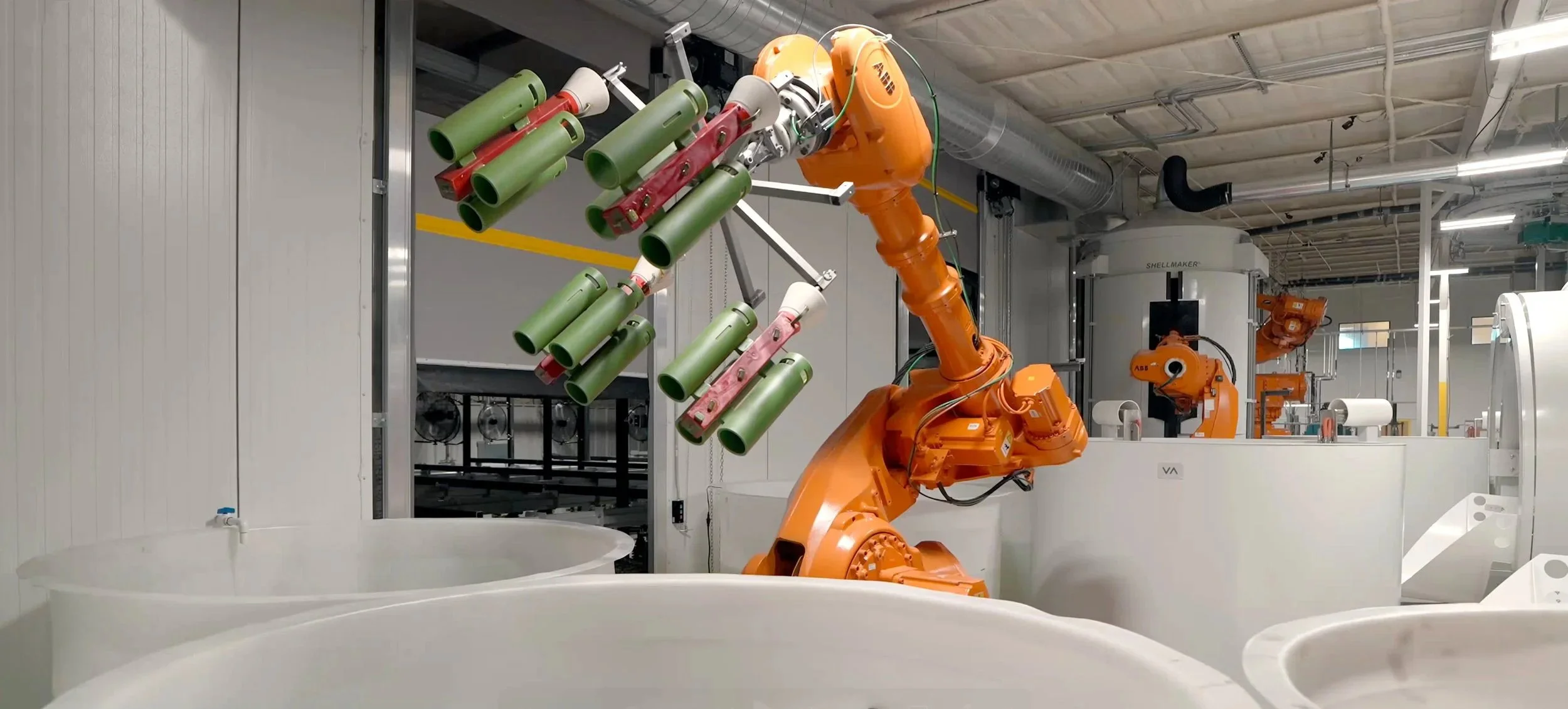

Facility Upgrades

IPC Cuts Lead Times & Improves Part Quality

In this case study, explore how we created a 5:1 increase in parts-per-shift by internally engineering a dual-cutting robotics system. With this upgrade, IPC Foundry Group laid the framework for dramatically reduced turnaround times and greater consistency & quality across its cast parts.