FAQ: Investment Casting C95500 Nickel Aluminum Bronze

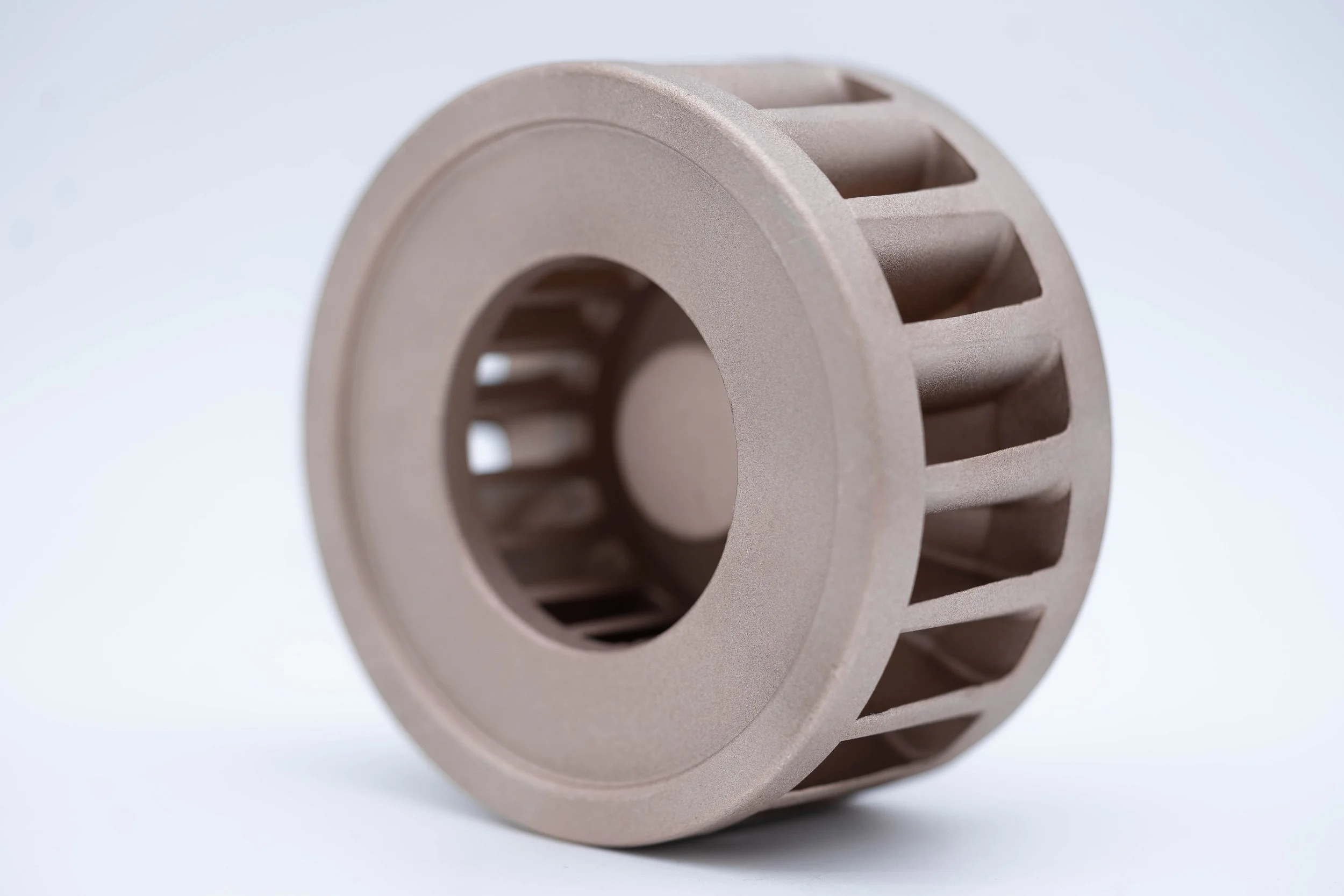

C95500 Nickel Aluminum Bronze Castings are commonly used in pump and valve components due to their strength and corrosion resistance.

Welcome back to our Foundry FAQ blog series. Here, we examine the alloys, processes, production, and the ins and outs of an investment casting foundry, all in 5 minutes of read time or less. Today's topic? Casting C95500 nickel-aluminum bronze, let's get into it!

What is C9500?

C95500, also known as Nickel Aluminum Bronze, is one of the toughest non-ferrous alloys in the world. It is the highest strength standard copper-based alloy, making it particularly suited for heavy-duty applications where other bronzes would fail. It is commonly used in the oil and gas industries, the marine industry, defense, and food processing.

The key to c95500's high performance lies in the addition of nickel (typically 3–5.5%), which, when combined with aluminum and iron, creates a material that rivals the strength of many steels while maintaining the superior corrosion resistance of copper.

What are the Benefits of Investment Casting C95500 vs. Sand Casting?

Investment casting provides a much smoother surface finish and tighter dimensional tolerances (often ±0.005 inches per inch). These are huge because nickel-aluminum bronze is an alloy that is difficult to machine. By using investment casting, you get a near-net shape part that requires minimal secondary operations (work after casting), saving you time and costs.

Can C95500 Achieve Thin-Wall Sections in Investment Casting?

Simply put, yes, it can!

One of the most significant advantages of the investment casting process is the ability to cast thin, intricate walls. This is particularly useful for C95500 applications such as pump impellers or aerospace valve bodies, where reducing weight without sacrificing the alloy's high tensile strength is a priority.

Does Investment Casting Improve the Corrosion Resistance of C95500?

While the chemical composition of nickel aluminum bronze determines a part's intrinsic resistance, the surface finish you can achieve with an investment casting helps even more. A smoother surface has fewer microscopic pits where salt or corrosive chemicals can pool. For marine or chemical processing hardware, this means the protective aluminum-oxide film can form more uniformly across the part.

Investment Casting allows for thin walls and complex geometries in copper-base alloy parts.

Should I Use Machining or Investment Casting for Nickel Aluminum Bronze?

This answer depends on your specific needs, as size, complexity of design, and the number of parts being produced can all impact which option is best for you. This being said, here are a few benefits of opting for an investment casting:

1) Near-Net Shape Casting

Because investment casting uses a ceramic shell formed around a precise wax pattern, your metal part comes out of the mold almost exactly like the final design. For an expensive alloy like C95500, this reduces the amount of expensive metal turned into waste during machining. In short, you pay for the metal that stays on the part, not the metal on the floor.

2) Cost and Time Savings when Producing in Bulk

If you are producing a medium to large volume of parts, the cost savings per part will be a powerful reason to choose investment casting.

As for time savings, while investment casting is slower to start than machining (prep time includes tooling, gate prep, flow analysis, etc.), once production is up and running, it can create parts significantly faster than machining. The precision casting process allows foundry workers to cast dozens of parts in one go with tree and gating systems as opposed to machining one part at a time.

Is Heat Treatment Necessary for C95500 Investment Castings?

It depends on the application. C95500 has excellent as-cast properties, but for extreme-stress environments (like aircraft landing gear or high-pressure valves), a quench and temper heat treatment can boost tensile strength. Investment castings respond very well to these treatments due to their fine, uniform grain structure.

Does IPC Foundry Group Offer C95500 for Investment Casting?

We do! IPC Foundry Group pours C95500 nickel aluminum bronze out of both of our domestic foundries in Texas and Utah. If you’re seeking a US-based investment foundry, contact us today, and see how we can save you time and money on your next production cycle.