Introduction

Gate Removal & Finishing Work

An often-overlooked aspect of the investment casting process is the finishing work that follows metal pouring. These critical additions to the process prepare castings for market but can require a significant amount of time.

A major finishing operation, one that is undertaken in every investment casting project, is gate removal. Gates are the channels that connect each individual part to a runner system that allows for metal pouring. During the casting process, molten metal flows through these systems and gates to fill the molds that form the final parts. Gate systems allow foundry workers the ability to pour multiple parts in one go, as well as manage the speed and direction of molten metal entering the mold - ultimately preventing defects and ensuring that parts both form and cool correctly.

A foundry worker assembles a mold.

Gate removal, as the name suggests, is when gates are cut away (manually or via automation) leaving behind the finished part(s). For large-scale productions, this can significantly increase workload and lead times - especially whenever manual work is involved.

The Problem

A Production Bottleneck

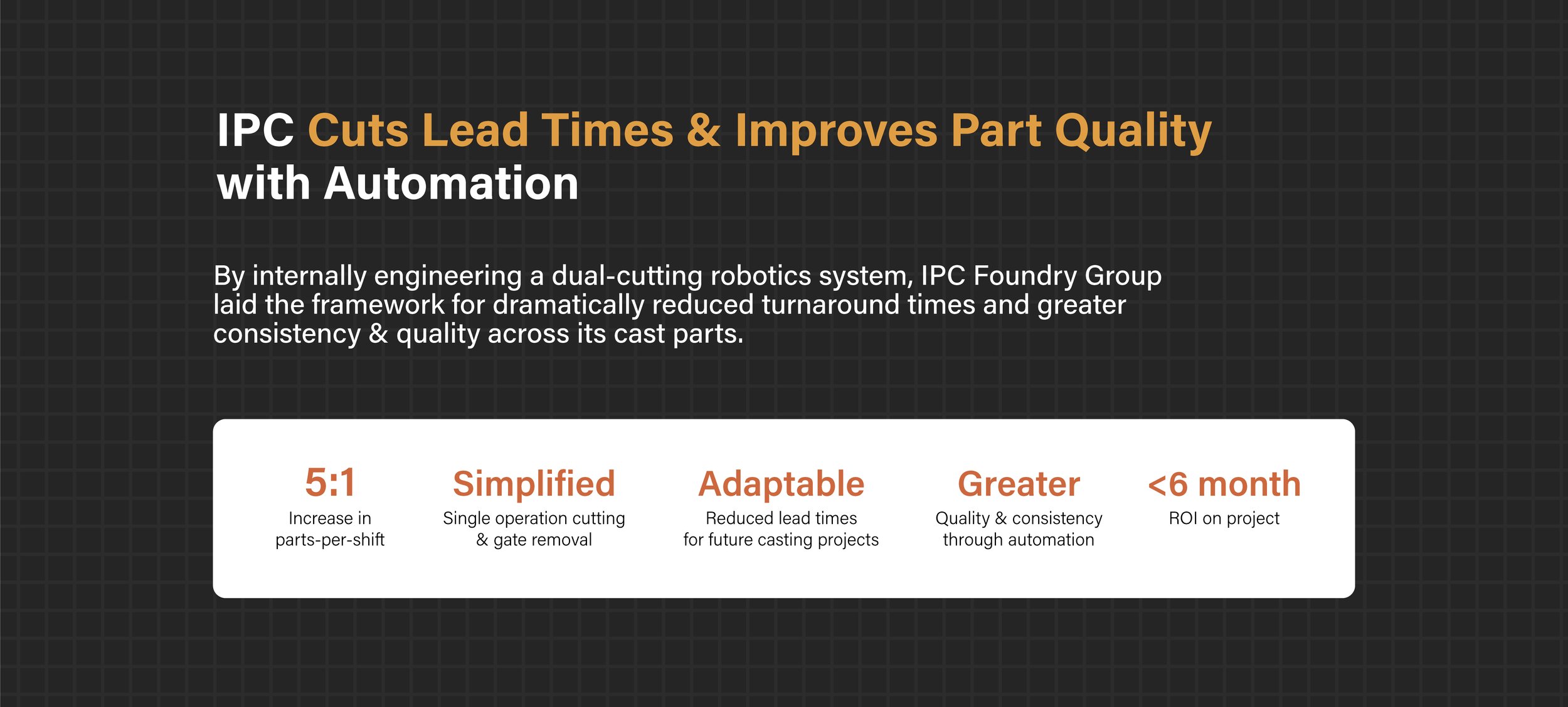

IPC produces over 2 million pounds of metal parts annually for customers in more than 130 industries. With such a workflow, identifying production bottlenecks is crucial to meeting delivery times - it also makes for a unique challenge in introducing changes without disrupting service.

In late 2024, we recognized an opportunity to improve production flow for a customer that we produce ~20,000 parts for annually. At the time, these parts required significant operator oversight during gate removal. Each part needed to be hand-loaded onto robotics for cutting. Furthermore, the castings needed multiple manual cutting and hand-grinding processes to finish each unit. Our method at the time was effective but inefficient; across 20,000+ parts annually, it led to production variability, numerous man-hours, and lots of downtime.

IPC has always focused on improving our operations, so, with these bottlenecks in mind, our engineering team got to work. We upgraded our robotics to enable single-operation cutting and automated loading. These changes led to a considerable reduction in both manual labor and downtime while also allowing us to utilize the razor-sharp consistency baked into automated cutting. The result? Cleaner cuts, less operator oversight, and significantly increased throughput through automation.

What We Did

Our Solution

IPC Foundry Group’s Scott Veenker and Daniel Chamberlain took on this challenge and sat down to discuss their upgrades and what they mean for future casting projects at IPC.

Let’s get into the details!

01 Installation of PLC (Programmable Logic Controller)

One addition to our existing robotics was the implementation of a PLC (Programmable Logic Controller), which allows operators to set and select premade cutting operations for different parts, all in one central location. PLCs are essential for tasks like managing multiple robots in a cell, ensuring safe and efficient operation, and handling complex sequences of movements.

Here’s Scott on this cell of robotics:

“This cut-off cell takes what used to be a four-step process procedure and made it into one. You load the robot one time and it does four operations…. and does it much more exact than an operator can do it every time.”

What does this change do?

Facilitates the control of multiple robots at once (allowing us to run complex tasks simultaneously).

Stores numerous cutting protocols (allowing us to seamlessly switch between jobs).

Enables single-operation cutting through programmed sequences, eliminating or dramatically reducing manual cutting.

02 Custom Grippers and Loading Station

As mentioned above, one major bottleneck to previous production was the manual loading of each part onto a cutting robot; this had to change. To fix it, we developed a new loading station to significantly reduce manual oversight, as well as custom grippers to enable automated pickup of each part.

Here’s Scott on the previous situation:

“Every five minutes an operator needed to be ready to pull a part off and put a new one on. So now with this loading station, an operator can load several parts at a time, and then walk away, do another operation at a different machine, and then come back and reload them.”

Daniel Continued:

“There's no downtime between cutting those... As soon as one is cut another starts. And if an operator sees space that’s available, they could go out and swap in a part at any time and the cell would run continuously - like clockwork.”

“It's increasing throughput by letting the operator have more free time to do his other jobs.”

What does this change do?

Enables continual cutting of parts with dramatically reduced downtime

Frees up foundry workers to engage in other finishing operations

15+ minutes saved/hour by eliminating manual loading delays.

03 Installation of VFDs

Another update to our cutting robotics was the introduction of two VFDs (variable frequency drives), which allow us to set optimal speeds for cutting different thicknesses of gates as well as different material types.

This presented a unique challenge to the team and required quite a bit of troubleshooting to not halt production.

Here’s what Daniel had to say:

“Something that I felt responsible for was the VF (variable frequency) sizing of the VFDs where we're using such high loads on our motors. By doing the proper measurements beforehand, we wanted to make sure we got everything right for the first time. At first, our VFDs were underpowered because we were overpowering our motors.”

After testing and power tweaking, they were able to lock it in. The lessons learned from this VFD integration will pave the way for smoother setups in upcoming robotics projects.

What does this change do?

Allows for more precise, controlled cutting as blade speeds are set to match the task at hand.

Provides a safer environment for workers as VFDs can halt blades when needed with fine-tuned start-stop control.

04 Installation of Photoelectric Sensors

On each cutting station, we also installed six photoelectric sensors. These sensors ensure that parts are picked up autonomously, held in the correct position, and cut accurately.

Two of the photoelectric sensors are pictured here.

Installing these sensors also helped eliminate failure points in our finishing work.

Here’s Scott on one of these failure points:

“There were times where the wear pattern of the cut off wheel would cause the gate not to come all the way off - and then it would continue grinding and tear it up and ruin the part. So an operator kind of had to be babysitting to make sure that things went well… just adding one sensor was a big deal in reducing how much we have to monitor.”

What does this change do?

Ensure razor-sharp precision and consistency in gate removal

Stops cutting in the event of a failure

Assists robots in picking up parts of various shapes and sizes

Significantly expedites the gate removal process

05 Adaptability for Future Projects

Production ramped up quickly. After a gradual initial rollout, shift output jumped to 70 parts and soon thereafter to over 110 parts per shift. Optimizations are still ongoing, but these additions to our cutting robotics allowed for greater throughput and increased quality in every part produced. Overall, we experienced an estimated 5:1 increase in output per shift.

The team had this to say on the evolution of output:

“Back in the day we were doing maybe 20 of this of these style parts a week and cutting them on a chopsaw manually. And a guy would spend pretty much the whole day cutting these off to do 20 and then do three more operations after that. Today we're doing 110 plus in one shift. And that's not even at full capacity by any means…

I could easily see us do 1,500 to 2,000 a week."

While the results are already promising, the real impact of these upgrades is still to come. Their flexibility and adaptability enable us to apply them across future projects—delivering lasting value to our customers.

Big Picture

IPC invests in its Customers

At IPC, we strive to be a production partner you can count on for all your metalworking needs through facility advancements, continually growing capacity, and exceptional quality in each of our castings.

We completed the installation of these updates in early 2025 without ceasing foundry operations or throttling other projects and saw a return on our investment in just a few short months.

In addition to internal advancements, we were able to get our customer to market faster than ever with greater consistency part-to-part.

Scott had this to say about the project:

"As a business, we have always had this mentality of trying to automate and reduce steps in the process. Not only did this last upgrade do this, taking what used to be a four-step process procedure and turning it into one - it also did it with much more exactness than an operator can do, every time.

Anytime we can see an opportunity like that - we spring into action."

Looking forward, the facility upgrades from this project have been designed with adaptability in mind—positioning us to support a wide range of future casting projects with faster lead times and superior part quality.

The improvements won’t just stop here, we’re always on the lookout for ways to optimize our production - Stay tuned!

Conclusion

Set Your Expectations High with IPC

Whatever the demands of your casting project, at IPC, we are willing to create or invest in a way to make it happen. Our modernized foundries and engineering experts allow for unique optimizations in every project. When needed, we won't shy away from upgrading our arsenal to meet your needs.

If you would like to see how IPC can save you time, money, and headaches on your next casting project, contact us today!