Introduction

Updates to Our Investment Casting Foundries

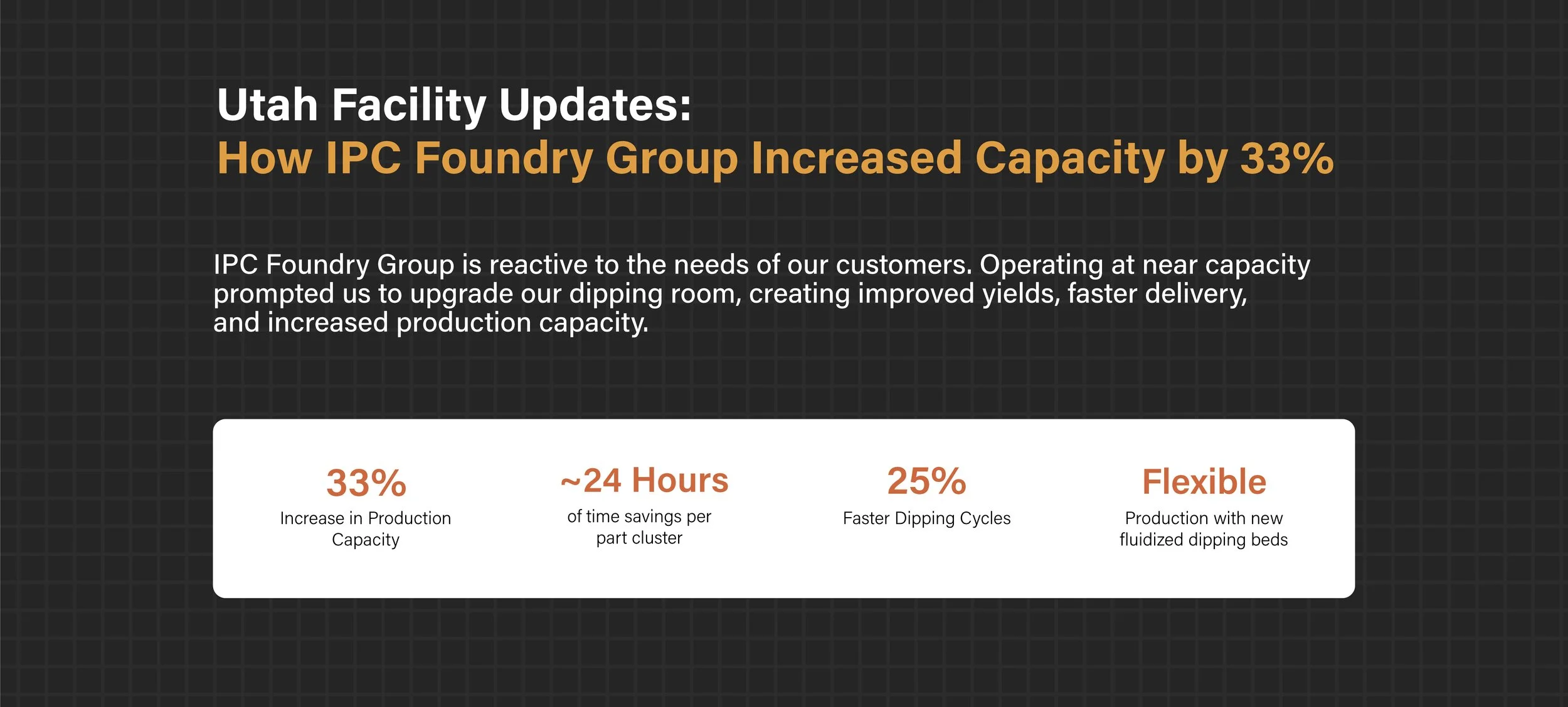

Every investment casting project starts with a customer need. At IPC, we've built our culture around responding quickly and effectively to those needs, whether that means adjusting workflows, introducing new equipment, or rethinking how we do things at our foundries. In 2025, we introduced significant improvements to both our Utah and Texas facilities, and we'd like to share some of them with you!

In part one of this two-part series, we'll explore recent updates to our Utah facility that showcase our culture of improvement in action. Part two will focus on updates to our Texas facility. All of these improvements come with direct benefits for you, our customers, including quicker turnaround times, higher-quality castings, and production wins for your business. Let's get into it!

An Analogy

Simple Changes, Big Differences

Speaking of cultures, we’d like to begin this article by using an analogy: sourdough breadmaking. Recently, the writer of this article made a trip to Costco and discovered a sourdough kit on sale. With racing thoughts of freshly-baked bread and a quick impulse buy, a new hobby was born.

To make a proper loaf of sourdough bread, there are dozens of seemingly trivial steps that can make a massive difference in the final product. For example, adding incrementally larger amounts of flour to your starter will assist in fermentation, and adding ice cubes to your baking pan can increase the springiness of your dough. Similarly, implementing new facets to the investment casting process can produce dramatic results in turnaround times, consistency, and quality.

The Problem

Operating Near Capacity

We’re a busy foundry! In 2024, we poured more than 2 million pounds of metal parts for customers across dozens of different industries. At times, we would produce so many parts that our dipping robots couldn’t keep up with demand, and our production team would have to hand-dip a portion of the parts to meet delivery timelines. While hand dipping is effective for select projects, it creates a significant amount of downtime during production and does not create shells as consistently as automated dipping.

The reliance on hand dipping highlighted an opportunity for improvement, and our engineering team sprang into action.

Room for Improvement

Dipping Room Upgrades

To better understand our recent updates, it helps to get up to speed with the dipping process. In this step of production, wax patterns of your soon-to-be metal parts are coated in a ceramic mixture to form a mold for metal pouring. As a part of this process, parts are typically dipped in a wet slurry and then coated with powder (using rainfall sanders or other methods) to finish the shell. Shellforming generally requires multiple dip and drying cycles, and at IPC, we use a climate-controlled conveyor system to automate the process.

Getting shells right takes time and effort; they must be strong enough to withstand the extreme heat of molten metal and precise enough to maintain the accuracy of the part.

Before our recent updates, our setup featured two dedicated robots: one for primary dipping (initial coats) and another for secondary dipping (all remaining layers). This separation allowed us to monitor dry times more effectively, keeping the early dips on one conveyor track while the slower secondary dips proceeded on another.

However, when operating at near capacity, the limitations of this setup became apparent. The robot responsible for primary dips (robot one) would finish its work, while the secondary robot (robot two) would fall behind due to its longer dipping and drying cycles. Secondary dips take longer to dry because they have additional layers of material. As an example, compare drying times between a swimming suit in open air vs. putting a pair of sweatpants over your wet swimsuit. The system in place created a bottleneck that was slowing down production times and necessitated hand dipping; we knew we had to make changes.

A cluster of parts being dipped in a ceramic slurry

A rainfall sander in action

A cluster being placed on our conveyor system

Hand dipped parts in a drying cycle

Upgrade 1

Hybridized Robot

Rather than separating our robotic lines between primary and secondary dips, we hybridized our primary dipping robot (robot one) to pivot between jobs and dipping types. We utilize a barcode system on our robotics to scan and recognize each part cluster and its position in the dipping cycle. By introducing a logic update to this system, robot one could seamlessly transition between jobs and assist in clearing the backlog of secondary dips. To perform these different tasks, we also had to install new slurry tanks and add additional rainfall sanders to our lineup. This way, robot one had the tools at its disposal to tackle its new workload. With these changes, robot one moved from dipping 96 part clusters per day to 192 clusters per day, a 100% increase in output.

Upgrade 2

Conveyor System Logic

To complement our new system, we also updated the conveyor tracks. Previously, robot one placed part clusters on the primary conveyor, where they completed their initial drying cycles without fans so the layers wouldn’t dry too quickly and become brittle. For secondary dips, clusters were shifted to a separate track equipped with fans that assisted in drying parts with multiple layers.

With robot one now handling both primary and secondary dips, the primary conveyor line required an update. To ensure that each dip dried appropriately, we installed a logic system that scans each cluster and automatically turns nearby fans on or off as needed.

Upgrade 3

Fluidized Dipping Bed

While reconfiguring our dipping floor, we also installed a fluidized dipping bed that provides an alternative method for shell forming. Simply put, it allows us to pick and choose between rainfall sanding or the new fluidized method to create the best shell possible on a part-by-part basis. The addition of the fluid bed provides tons of flexibility in shell forming. In one case, it enabled us to eliminate an entire dip cycle from production, saving over 10 hours of production time for each part cluster.

This fluidized bed originated from our Texas facility, which recently underwent a major robotics upgrade. We’ll cover those improvements in detail in part two of this series. Stay tuned!

Here’s a note from our engineering department on these changes:

“With each of these additions, we can internally change our recipes and our system knows what to do. From switching to fluid beds, turning on fans at different times, or introducing new parts, all we have to do is update our recipes.”

Conclusion

The Big Picture

Much like the sourdough example at the beginning of this article, these small “recipe changes” to our process have created outsized results for our customers. They’ve boosted part-to-part consistency, cut lead times, and significantly expanded our production capacity.

Better yet, we introduced these improvements entirely in-house while keeping production running without interruption. These changes in output also allow us to be reactive to our customers’ needs, whatever they may be.

At a Glance

What these Updates Achieved

Increased production capacity by 33%

Reduced dipping cycle times by 25%

Saved more than 24 hours of production time per part cluster

Enabled seamless integration of new or rush projects

Provided option to use either fluid bed or rainfall for optimal shell results

Improved shell consistency by reducing or eliminating hand dips

Implemented conveyor and robotic logic systems to handle larger projects

Why Choose IPC?

Your Investment Casting Partner

Have a unique production challenge? Count us in! At IPC, we strive to be the premier investment casting foundry in North America. With more than 45 years of casting experience and rich expertise in dozens of industries IPC Foundry Group is a production partner you can count on for all of your metalworking needs.

We can’t wait to get started! Contact us today.