IPC Invests in its Customers

Everything is Bigger

at IPC Texas

At IPC, we're built to be reactive to our customers' needs. When production was running near capacity, we didn't just hope for the best, we invested heavily to expand and improve our operations.

In part two of our two-part series, we’ll cover the recent major upgrades at our Texas foundry that directly result in quicker turnaround times, higher-quality castings, and greater dependability for your business.

If you missed it, you can check out Part One on the Utah facility upgrades here

TL;DR

Just Here for the Cliffnotes?

Here’s our TL;DR (Too Long; Didn’t Read)

Our commitment to our customers drove significant upgrades at our Texas facility. By implementing expanded robotic dipping and a new 50-ton wax press, IPC Texas boosted its production capacity by eightfold. These changes promise faster turnaround times and long-term dependability. While external professionals quoted our expansion at ~$3 Million, we executed the work internally for ~$1 Million, showcasing our ability to invest strategically and efficiently for the benefit of our customers.

Read on to see exactly how we're investing in our foundry to better serve you.

Casting 101

About Shell Formation

Before we get into the robotics and our upgrades, let’s talk about the dipping room and its role in the investment casting process. During a production cycle, this is where a wax pattern (a 1:1 replica of your part) is dipped and coated in ceramic multiple times to form a hard outer shell, which becomes the vessel for metal pouring later in the process.

You can relate shell formation to painting. Multiple wet layers dry over time to form the finished result, be it a painted wall, whitewashed fence, or piece of art! If you've ever painted a bedroom, you've probably experienced some of the headaches that come with touching a wall before it is dry or applying too thick a coat and watching lines of paint stream to the floor. Getting it right takes time and effort, but it makes a huge difference in the end result.

Similarly, the quality of the shell means everything to your castings. Each layer must be uniform, consistent, and properly dried before the next one is applied. If anything is amiss, it will appear in the casting as defects or, in extreme cases, an outright failed part.

Hand Dipping V. Automation

Investment Casting shells can be dipped by hand or via automation. A skilled worker can create exceptional results using hand dipping, but there are some drawbacks.

Hand Dipping Drawbacks:

Requires more time per part.

An increase of down time and turnaround times.

Due to their weight, large part clusters can put significant strain on workers.

Some parts are simply too heavy to dip by hand.

No matter how skilled the workers are, you will experience variability in shell consistency.

Utilizing automation enables consistent dipping and drying cycles while also taking strain away from workers. More on that later!

What We Did

Texas Foundry Upgrades

Prior to our recent upgrades, IPC Texas operated on a hybrid dipping system that used a combination of hand and automated dips. For the primary dips (initial 1-2) parts would be dipped by hand before transitioning to robotics. Secondary dipping (all remaining dips) would be performed by a single robot.

IPC is a high-volume foundry, pouring over 2 million pounds of metal components in 2024 alone. With this workload, our solo dipping robot often faced a backlog, forcing us into more hand dipping to meet demand. This manual process created a drag on efficiency and placed considerable physical strain on our team members lifting and dipping heavy part clusters.

Exploring Our Options

To resolve these concerns and ensure future success, we sought an external quote for a dipping room upgrade. That quote included a roadmap that required significantly expanding the size of our building and spending roughly 3 million dollars on new equipment and installation.

Rather than outsourcing, we bet on our own team. Our engineering department drew on its deep expertise and unmatched understanding of our operational needs to get the job done. They completed the dipping room upgrades without expanding the building while keeping total costs at approximately $1 Million.

The Upgraded Dipping Room

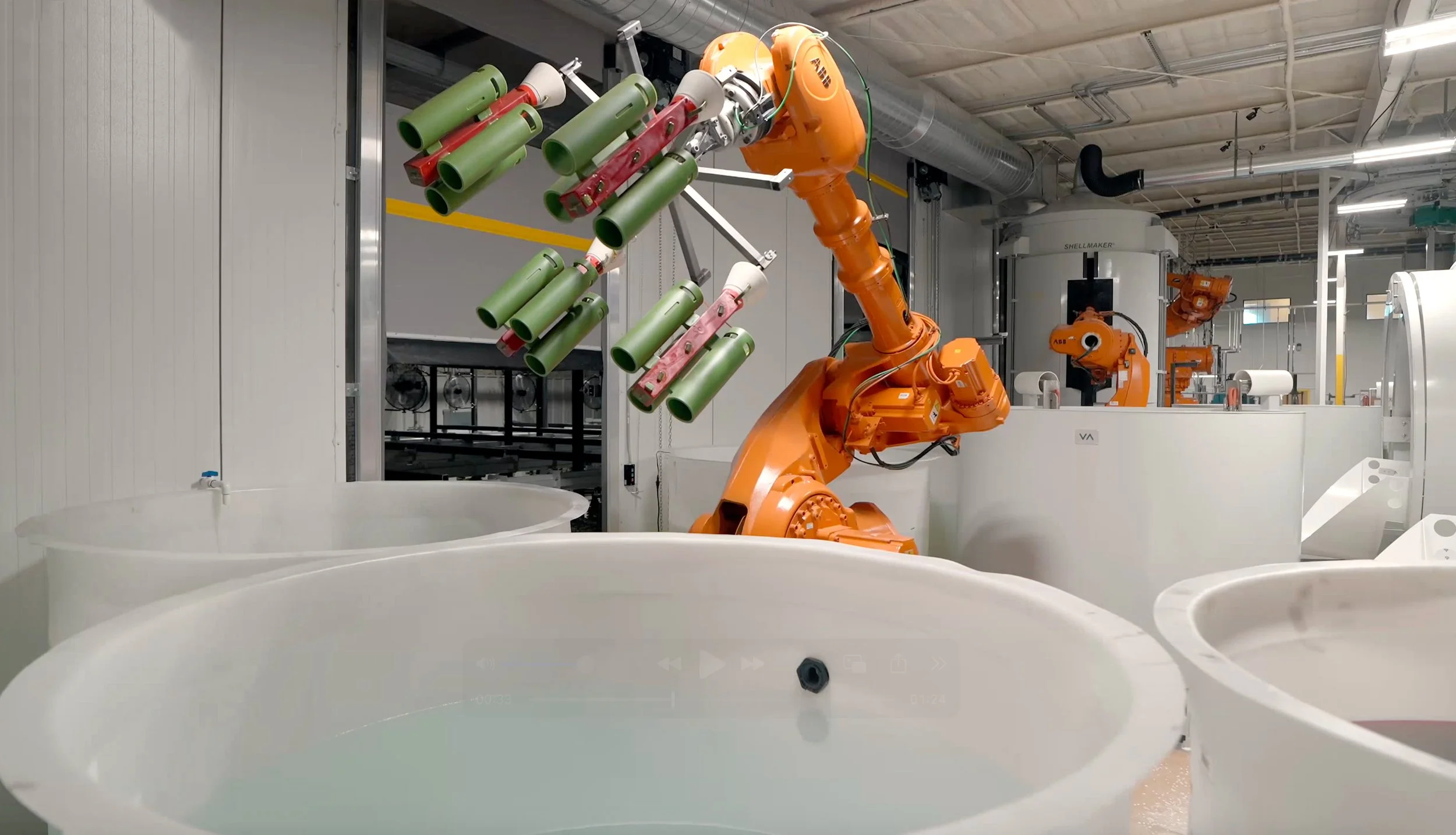

Without getting too deep into the details, we installed a fully-automated 3-robot dipping system that can dip eight part clusters at a time. For context, a part cluster is an engineered assembly where multiple wax patterns are arranged around a central channel, or sprue (see photos below). Utilizing clusters ensures optimal metal flow during the pour, while also enabling our foundry workers to process and pour multiple parts in a single action, significantly improving our throughput.

The wax pattern (green) being attached to a sprue (red).

Another wax pattern being attached to a sprue.

Several part clusters being dipped simultaneously.

Dozens of wax

patterns on a single sprue.

As part of the new system, we also installed three independent drying conveyors, enabling us to fully automate dipping from primary coats to finished shells. After each dip, our robotics automatically place the clusters onto a conveyor track where they complete a drying cycle precisely synced to their required cure times. After completing a loop, the clusters return to the robots, where the dipping and drying process repeats like clockwork until the shell is finished.

Once completed, shells are automatically transitioned to a separate conveyor that moves them forward to the next phases of production.

Additional Updates

In addition to the new automated dipping room, we recently installed (in Summer 2025) a brand new 50-ton wax press to assist in our production efforts. This is a BIG press offering larger format casting options to our customers. The new press will work in tandem with our existing wax injection machines to provide higher quality injections and further reduced cycle times.

The Bottom Line

What These Changes

Mean for You

We mentioned above that hand-dipping inherently creates more downtime than automated dipping. Let’s get into that.

Installing our new dipping robotics reduced a 7-day process per part cluster down to just 3-4 days, essentially cutting this part of the production timeline in half. Automating shell formation has allowed us to begin introducing overnight dipping to our production line, which will further expedite our throughput.

Here’s Scott Veenker from IPC on what overnight dipping can accomplish:

“Dipping times can be cut down to exactly what it takes to dry the shell, which is typically 5 hours/dip. Meaning that if a part has 5 or 6 dips it could be completed in 25-30 hours.”

Scott continued,

“We designed the conveyors with that 5 hour dry time in mind. We put just enough clusters on each line so that following one full revolution every part is right on time for its next dip.”

To fully implement overnight dipping, we’ve needed to automate filling our rainfall sander (which applies part of the ceramic shell) as well as introduce logic to our robotics that enables them to adjust to changing slurry levels throughout the night. We’ve nearly locked in both of these additions and anticipate 24/7 dipping cycles at IPC Texas by the end of 2025.

In short, dips that used to take nearly a week to complete can soon be completed in 1-2 days.

Additional Highlights

Wrapping Things Up

We mentioned above that we were quoted $3 Million for the project, but completed the work internally for ~$ 1 Million. With the savings we’ve achieved, we’re investing more in our facilities, including new flashfire dewaxing systems and more that we’ll share with you in 2026. Stay tuned!

Speaking of investing in ourselves, our new automation allows us to reinvest in our staff by elevating their roles.

Here’s Scott again on these additions:

“The goal of adding robotics and automation isn’t to reduce our workforce, but to increase our capacity while maintaining our staff who won’t have as much strain on their bodies from operations like hand dipping.”

By eliminating the repetitive, manual workload, we significantly reduce the physical strain on our team and unlock their time for more rewarding, high-value work. This is a chance for our talented production staff to focus on complex tasks that require human expertise, such as advanced quality inspections and specialized finishing. Work that directly adds superior value to your final components with no time lost.

Since introducing these changes, we’ve seen an estimated eightfold increase in capacity at IPC Texas. Overall, these upgrades will allow us to confidently meet customers’ deadlines and scale with their needs going forward while maintaining the exceptional quality and consistency that IPC has delivered for over 45 years.

Happy to Call Texas Home

Check Us Out

Recently, IPC Foundry Group and our new robotics were featured by the Marble Falls Economic Development Corporation. Hear from Blake Williams, President at IPC Foundry Group, and catch a quick look at our new system in this 90-second video.

Conclusion

What’s Next for IPC?

At IPC Foundry Group, our goal is to be the premier investment casting foundry in North America. The recent upgrades at both our Utah and Texas facilities are not a finish line for us, but tangible proof of our commitment to continuous improvement and our ability to remain highly reactive to your needs.

We aren't slowing down. As of October 2025, we are actively pursuing crucial quality certifications, such as ISO 9001 and CMMC Level 2, and will share a progress update on these certifications soon. We will continue to invest in all of our foundries, ensuring that IPC remains a dependable, long-term partner producing the highest quality castings possible.

Ready to see how our new capacity can accelerate your next project? Contact us today.