What is Tooling for Investment Casting?

In this article, we'll take a look at one of the initial steps in the Investment Casting process, tooling! Our goal is to have you understand the basics, answer a few FAQs, and leave you better informed about our industry in 5 minutes or less. Let's get into it!

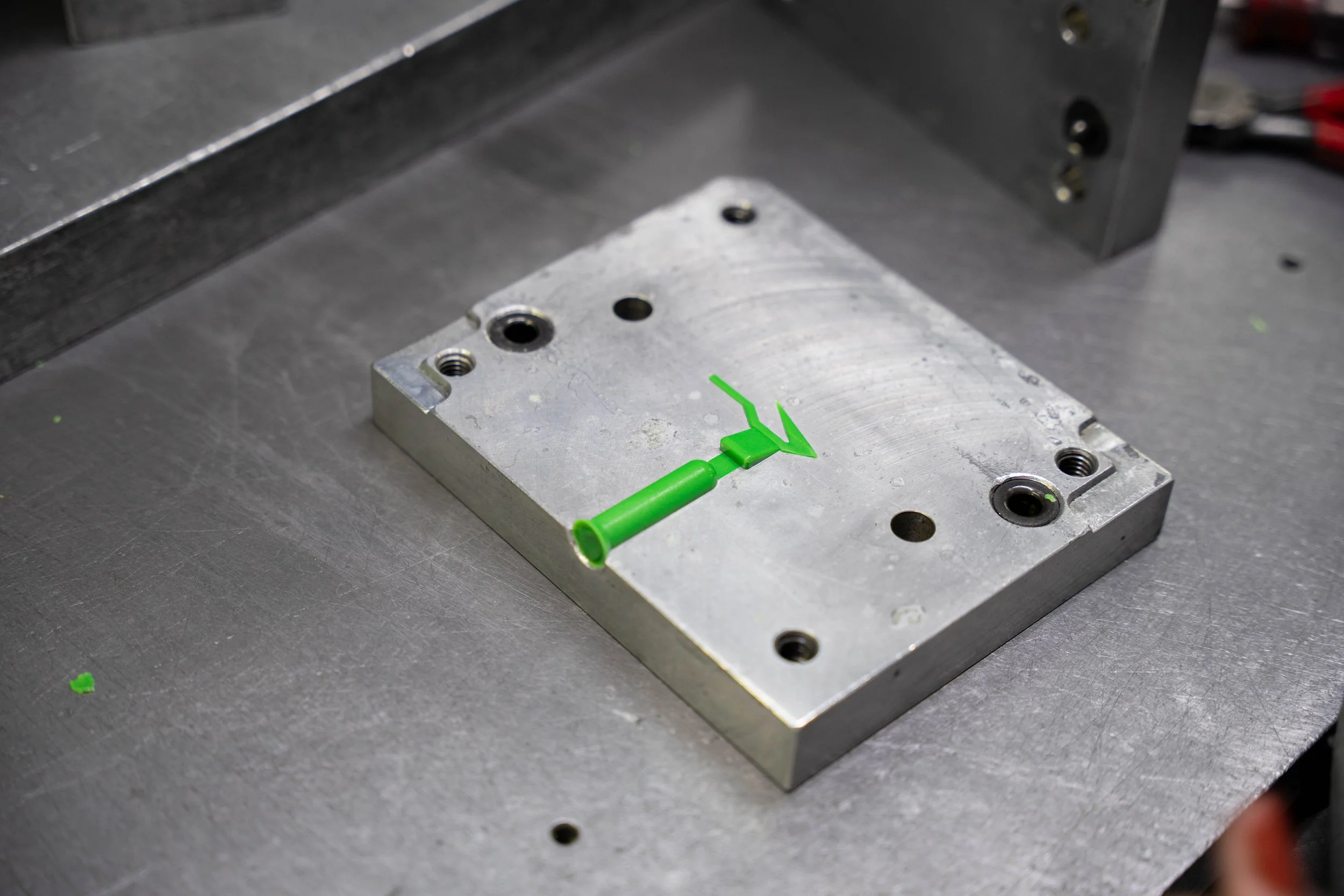

A freshly injected wax pattern being removed from a tooling

What is Tooling?

If you've ever used an ice cube tray or a cake pan, you've experienced the power of a mold; something that allows you to replicate or reproduce an item hundreds, if not thousands, of times. Tooling is where an investment caster creates a mold that enables you to produce your metal part(s) over and over again.

If you're unfamiliar with the casting process, here's a quick 101 that will showcase where tooling comes into play:

Step 1: Tooling

A tooling is made using your part's 3D model. This tooling will be a hollow die of your part. Compare this to our ice tray example from above (some toolings are quite complex; more on that later).

Step 2: Wax Injection

Foundry workers will use wax injection machines and your tooling to produce wax patterns. A wax pattern is a replica of your part that will be used to form a shell for metal pouring.

Step 3: Shell Formation

Wax patterns from the previous step are dipped in a ceramic slurry several times to create a hard outer shell around the wax. This hard outer shell will serve as a mold for eventual metal pouring.

Step 4: Dewaxing

After a sufficiently strong shell is formed, foundry workers will remove the wax pattern from the shell, typically using a flashfire oven or autoclave. The remaining hollow shell is prepared for metal pouring.

Step 5: Metal Pouring

Foundry workers pour your alloy of choice into the shell. Once the metal cools and hardens, the outer shell is removed, and your part is ready for finishing work.

Step 6: Finishing Work

After pouring, your part will undergo finishing work to get your part 100% ready for the market. This can include a number of things, including but not limited to: gate removal, heat treating, non-destructive testing, painting, plating, welding, sanding, and machining.

Why is Tooling So Expensive?

Put simply, the tooling needs to be exceptionally accurate and durable, which requires quality materials, precision machining, 3D modeling & CAD work, prototyping, and other testing. However, tooling is not one-size-fits-all; costs can vary greatly depending on the size and complexity of your part.

What factors into cost?

1) Custom Work:

Each investment casting project is unique. Unlike generic molds, investment toolings are engineered to extremely tight tolerances to ensure the final metal casting meets dimensional and performance requirements.

2) Quality Materials and Durability

Tooling is commonly made from hardened steel or aluminum, allowing it to handle thousands of wax injections without warping. Depending on the size of your part, material costs can significantly increase the tooling cost.

3) 3D Modeling and Machining

To make accurate molds, engineers and tool makers will utilize 3D modeling, flow simulations, and high-precision machining to get your tooling perfect for production. Even with modern technology, tooling still depends on human expertise. Toolmakers hand-fit, polish, and finish each mold to ensure perfect alignment and a smooth wax surface. That combination of technology and craftsmanship adds both value and cost.

4) Part Complexity

The complexity of your part directly affects the complexity of the tooling. A straightforward component may only need a single-cavity die, while designs with internal features, thin walls, or overhangs require precision-engineered, multi-piece tooling that allows foundry technicians to replicate those details accurately.

5) Support Tooling

Beyond the primary tooling, secondary or support tooling is often required for gates, runners, and assembly trees. These structures control metal flow and support multiple parts during casting. They also play a crucial role in process reliability and part quality, and their inclusion is reflected in the overall tooling cost.

6) Prototyping, Modeling, and Testing

Engineers will utilize software, prototypes, and test runs to ensure that the tooling will meet expectations. This can add costs and time to your production cycle.

Toolings can come in a variety of sizes and differing levels of complexity.

Do I Need to Use Tooling?

This is a question that requires some nuance. In the interest of brevity, tooling is typically recommended when:

1) You need ongoing or repeat production.

2) Your part design is stable (you aren't experimenting with design, and you'll produce the same parts for a long time).

3) You are producing a medium to large number of parts.

Can I Skip Tooling?

Yes! For small batch production runs, one-offs, legacy part work, or rush projects, 3D printing offers a great alternative to tooling.

Is Tooling Worth it?

If you’re considering investment casting, it’s important to remember just how much consistency and accuracy tooling brings to the process, especially for critical applications in defense, aerospace, medicine, oil and gas, and power generation. With a dedicated tool in place, you can produce parts with consistent precision for years to come. And while the upfront investment can seem significant, it often pays for itself through long-term efficiency and production savings.

Regardless of your industry, if you value consistent quality and are producing a sufficient number of metal parts, tooling is well worth the upfront cost.

An Analogy Using Snow Cones:

A few years ago, the author of this article purchased a shaved ice attachment for his stand mixer to make snow cones. The attachment included several ice molds that made ice cubes that perfectly fit the attachment and its cutting blades. The molds worked perfectly and helped serve some pretty stellar snow cones for months until one day, disaster struck. Two of the three molds slipped out of his freezer and shattered on the floor.

He later purchased replacements from Amazon and a third party, but these molds didn't have the same rigidity and were a cheaper material than the originals. Because he skimped out on cost, he also skimped out on quality, and the snow cones suffered. After one or two rough attempts at making snow cones with the new molds, he went back to the manufacturer and bought replacements for the originals and threw away the cheaper, silicone molds.

The above is a silly example of how investing in the right tools can lead to the results that you want. Quality tooling from a reputable investment casting foundry can be a game-changer for your business.

Why Choose IPC?

IPC Foundry Group has over 45 years of investment casting experience serving customers in dozens of industries throughout the US and Canada. If you'd like to learn more about tooling, our 3D printing and prototyping services, or see how we can save you time, money, and headaches on your next production cycle, contact our team today!